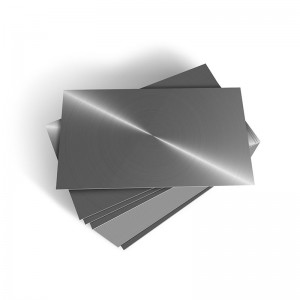

Stainless Steel Plate

| Thickness | 3.0~85mm |

| Width | 20~1524 mm |

| Length | 20~6096 mm |

| Surface Finish | No.1 |

| Edge | Slit o Mill |

Steel Grade

|

|

ASTM |

JIS |

AISI |

EN |

Mill's Standard |

|

Grade |

S30400 |

SUS304 |

304 |

1.4301 |

202 |

|

S30403 |

- |

304L |

1.4307 |

204Cu3 |

|

|

S31603 |

- |

316L |

1.4404 |

|

|

|

S43000 |

SUS430 |

430 |

1.4016 |

|

Other specifications are also available up to request.

|

Thickness Tolerance: According to 1/2 JIS G4304 |

|

|

Thickness |

Tolerance |

|

8.0 mm < T ≦ 10.0 mm |

±0.32 mm |

|

10.0 mm < T ≦ 25.0 mm |

±0.34 mm |

|

25.0 mm < T ≦ 85.0 mm |

±0.40 mm |

|

Length Tolerance: According to 1/2 JIS G4304 |

|

|

Thickness |

Tolerance |

|

T ≦ 10.0 mm |

-0 / +60 mm |

|

10.0 mm < T ≦ 85.0 mm |

-0 / +65 mm |

Chemical Composition

|

ASTM Specification |

|||||

|

ASTM A240 |

Steel Grade |

C% Max. |

Cr% Max. |

Ni% Max. |

Mo% Max. |

|

SUS304 |

0.08 |

18.0~20.0 |

8.0~10.5 |

- |

|

|

SUS304L |

0.03 |

18.0~20.0 |

9.0~13.0 |

- |

|

|

SUS316L |

0.03 |

16.0~18.0 |

12.0~15.0 |

2.0~3.0 |

|

|

SUS430 |

0.12 |

16.0~18.0 |

0.6 |

- |

|

Mechanical Property

|

ASTM Specification |

||||||

|

ASTM A240 |

Steel Grade |

N/m2 MIN. |

N/m2 MIN. |

% MIN. |

HRB MAX. |

Bendability: |

|

Tensile Stress |

Proof Stress |

Elongation |

Hardness |

Bending Angle |

||

|

S30400 |

515 |

205 |

40 |

92 |

No Require |

|

|

S30403 |

485 |

170 |

40 |

92 |

No Require |

|

|

S31603 |

485 |

170 |

40 |

95 |

No Require |

|

|

S43000 |

450 |

205 |

22 |

89 |

180° |

|

Stainless Steel Plate is used for industrial sectors and components for processing equipment for foodservice, medical device, chemical, petrochemical and power transmission industries.

The following gives a flavour of the full range:

1. Domestic

Cutlery, sinks, saucepans, washing machine drums, microwave oven liners, razor blades

2. Transport

Exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles

3. Oil and Gas

Platform accommodation, cable trays, subsea pipelines.

4. Medical

Surgical instruments, surgical implants, MRI scanners.

5. Food and Drink

Catering equipment, brewing, distilling, food processing.

6. Water

Water and sewage treatment, water tubing, hot water tanks.

7. General

Springs, fasteners (bolts, nuts and washers), wire.

8. Chemical/Pharmaceutical

Pressure vessels, process piping.

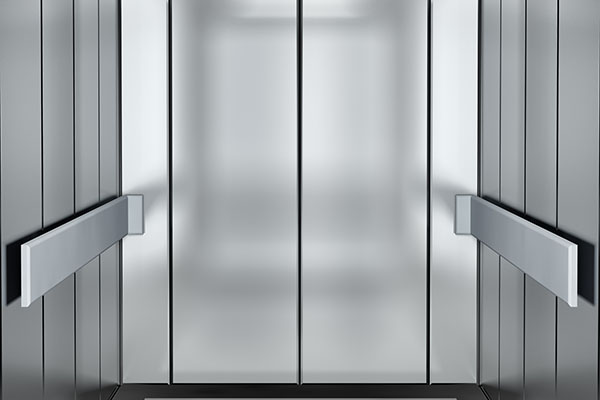

9.Architectural/Civil Engineering

Cladding,handrails, door and window fittings, street furniture, structural sections,reinforcement bar, lighting columns, lintels, masonry supports